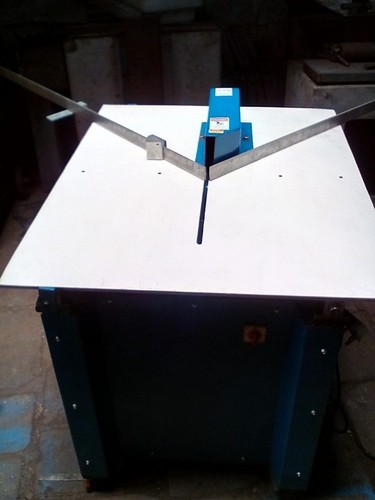

Motorised Photo Frame Cutting Machine

Product Details:

- Drive Motor Belt Drive

- Product Type Frame Cutting Machine

- General Use Plastic, Wood, Aluminium Cutting at 45 and 90 Degree

- Material Plastic, Alluminium

- Capacity 150 Pcs/hr

- Weight (kg) 150 Kilograms (kg)

- Computerized No

- Click to View more

Motorised Photo Frame Cutting Machine Price And Quantity

- 1 Number

- 48000.00 - 52000.00 INR/Piece

- 64000.0 INR/Piece

Motorised Photo Frame Cutting Machine Product Specifications

- 150 Kilograms (kg)

- 110 Millimeter (mm)

- Belt Drive

- No

- 150 Pcs/hr

- 780 * 750 * 750 Millimeter (mm)

- Circular Saw Blade

- 10 Square Foot (ft2)

- Plastic, Wood, Aluminium Cutting at 45 and 90 Degree

- Frame Cutting Machine

- Wood, Acrylic, Aluminium, Synthetic, Plastic

- 1 hp

- No

- Other

- Other

- 220 Volt (v)

- Electric

- High Torque, Low Noise, Environmental Friendly, Good Quality, High Efficiency, Low Energy Consumption

- Blue

- 12 inch

- 1 yr

- Plastic, Alluminium

- Manual

- 4000 RPM

Motorised Photo Frame Cutting Machine Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 100 Number Per Month

- 10 Days

- STANDARD PACKAGING

- All India

Product Description

Motorised Photo Frame Cutting Machine manufactured by our company are widely used for the cutting of wood and metal bodies at a faster rate with higher efficiency and excellent surface finish. It is a heavy duty machinery which is fabricated by using heavy engineered materials that gives rigidness and robustness to the frame of the machine. It is provided with a high speed electric motor which runs on standard power of 220 volts. Motorised Photo Frame Cutting Machine is also provided with measuring units which gives higher dimensional accuracy to the final product. The whole assembly is mounted on a set of castor wheels which makes it very easy to move this device from one place to another.

Versatile and Precise Cutting Solutions

Designed for both versatility and accuracy, this motorised photo frame cutting machine enables seamless cutting across a variety of materials including wood, acrylic, aluminium, and plastic. With adjustable angles and a robust steel structure, it suits diverse professional demands for frame manufacturing and material processing.

User-Friendly and Efficient Operation

Equipped with manual controls and an electric belt drive, the system combines straightforward usage with high performance. The machines environmental benefits, low energy consumption, and high-torque motor ensure a reliable and cost-effective solution for businesses focused on quality and productivity.

Durability and After-Sales Assurance

Manufactured from premium steel, aluminium, and plastic, the machine is built to last. With a one-year warranty backed by exporters, manufacturers, and retailers in India, users can expect long-term support and troubleshooting assistance for uninterrupted operations.

FAQs of Motorised Photo Frame Cutting Machine:

Q: How do I operate the Motorised Photo Frame Cutting Machine?

A: The machine is operated manually via a user-friendly control system. Start by securing your materialplastic, wood, aluminium, or syntheticon the cutting area. Set the desired angle (45 or 90), power on the 1 hp motor, and guide the material into the spinning 12-inch circular saw blade for efficient, precise cuts.Q: What types of materials can this machine cut?

A: This cutting machine can process a variety of materials including wood, acrylic, aluminium, synthetic, and plastic sheets. Its robust design and high-torque motor make it suitable for crafting photo frames and other items requiring precision and versatility.Q: When is maintenance required, and what does it involve?

A: Routine maintenance is recommended every few months depending on usage to ensure smooth operation. Key tasks include cleaning the blade, inspecting belt drive components, checking for loose parts, and replacing the circular saw blade after extensive wear or diminished cutting performance.Q: Where can I install this machine for optimal use?

A: The Motorised Photo Frame Cutting Machine should be installed in a well-ventilated workshop or manufacturing facility with sufficient space to accommodate its dimensions (780 x 750 x 750 mm). A flat, stable surface and access to a 220V electrical supply are essential for safe and efficient operation.Q: What is the process for achieving angled cuts?

A: To create angled cuts, adjust the cutting table or guide to the preferred angle (45 or 90). Secure your material thoroughly, and activate the machine. Steadily advance the material towards the blade, ensuring consistent contact for clean, accurate cuts.Q: How does this machine benefit my business operations?

A: With a high cutting speed of 4000 RPM and capacity of 150 pieces per hour, this machine boosts operational efficiency and productivity. Its low noise output, cost-effective energy consumption, and environmental friendliness contribute positively to both workplace comfort and sustainability goals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free