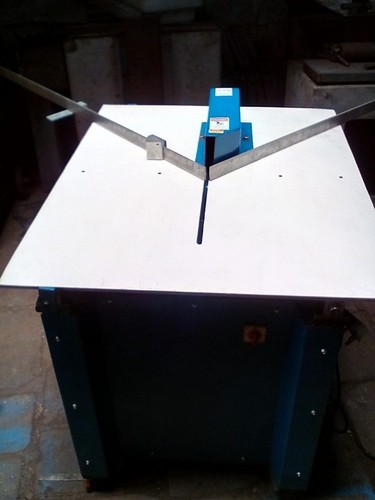

Electric Photo Frame Cutting Machine

62000.0 INR/Number

Product Details:

- Drive Motor High torque AC motor

- Product Type Electric Solid Frame Cutter

- General Use Cutting photo frame mouldings

- Material Mild Steel

- Type Other

- Capacity 100 Pcs/hr

- Weight (kg) 125 Kilograms (kg)

- Click to View more

X

Electric Photo Frame Cutting Machine Price And Quantity

- 62000.0 INR/Number

- 1 Number

Electric Photo Frame Cutting Machine Product Specifications

- High Torque, Low Noise, Good Quality, Environmental Friendly, High Efficiency, Low Energy Consumption

- 1 HP induction motor

- High torque AC motor

- Manual Control

- Other

- 1 year

- 3200 RPM

- 100 Pcs/hr

- 0.2 mm

- Rotary blade cutting

- Cutting photo frame mouldings

- Electric Solid Frame Cutter

- 110 Millimeter (mm)

- 12"

- No

- 15 Square Foot (ft2)

- 220 Volt (v)

- Mild Steel

- Compatible with standard design/photo frame cutting software

- No

- 780 mm x 750 mm x 760 mm Millimeter (mm)

- Other

- 125 Kilograms (kg)

- Wood, plastic, aluminium mouldings

Electric Photo Frame Cutting Machine Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 100 Number Per Month

- 10 Days

- STANDARD PACKAGING

- Asia, Central America, Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

The FM 6 Table Cutting machine is designed and engineered with a focus on durability, reliability and safety. The blades are easily adjustable for accurate angle and pitch. Satisfying the highest production and safety standards for operation keeping hands away from the cutting area and with its completely enclosed design, no motors or blades are exposed

Features of Table Cutting machine:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Outstanding Cutting Precision and Versatility

This advanced cutting machine achieves highly accurate results for straight, bevel, and mitre cuts, ensuring professional finishes with every use. Thanks to its robust rotary blade, it easily handles a variety of materials like wood, plastic, and aluminium mouldings, making it suitable for diverse framing requirements. Its computerized controls and digital display streamline the cutting process, improving both productivity and consistency.

User-Friendly and Efficient Operation

Designed for convenience, the machines setup takes less than 15 minutes and daily operation is simplified with LED status indicators and clear controls. The operating environments broad temperature and humidity range provides flexibility, and the quiet 65 dB operation allows comfortable use in most workspaces. Manual lubrication points ensure longevity, while air cooling maintains optimal machine temperature.

Safety, Durability, and Maintenance

Operator safety is at the forefront, with features including an emergency stop switch and blade cover. The steel and aluminium construction resists wear and tear, while the hardened steel blade provides lasting sharpness. Its low-maintenance design, aided by easy access lubrication points and a simple air-cooling system, ensures reliable performance for demanding production environments.

FAQs of Electric Photo Frame Cutting Machine:

Q: How do I set up the Electric Photo Frame Cutting Machine, and how long does it take?

A: Setting up the Electric Photo Frame Cutting Machine is straightforward and typically takes less than 15 minutes. Just ensure a 220V AC, 50Hz power supply is available, install the software compatible with standard photo frame cutting applications, and follow the provided manual to safely connect and initialize the machine.Q: What materials and frame sizes can this machine cut?

A: The machine is engineered to cut photo frame mouldings made of wood, plastic, and aluminium. It accommodates frame widths up to 110 mm and cutting thicknesses up to 12 mm, with a cutting area of 650 mm x 410 mm, making it versatile for various framing projects.Q: When should I perform manual lubrication on the machine?

A: Manual lubrication should be conducted regularly according to the manufacturers recommendations, typically after every few days of operation or as suggested in the maintenance schedule. Proper lubrication extends the machines lifespan and ensures smooth operation.Q: Where is the Electric Photo Frame Cutting Machine best used?

A: This machine is ideal for use in workshops, framing studios, and production environments run by exporters, manufacturers, retailers, suppliers, or traders who require reliable, high-volume frame cutting. Its robust design and safety features support safe installation in a variety of professional settings.Q: What is the typical process for operating the machine?

A: To operate, load your frame moulding, select the required cutting function (straight, bevel, or mitre) via the PLC digital controller, and monitor progress using the LED indicators. The high-torque AC motor and precise rotary blade ensure a smooth, accurate cutup to 200 frames per day can be processed efficiently.Q: How does this machine benefit my business compared to manual frame cutters?

A: The computerized system and electric drive significantly reduce setup and cutting times, deliver high precision (0.2 mm), and support higher capacity. This boosts productivity, ensures consistent quality, and allows operators to handle more orders with reduced physical strain and risk of error.Q: What safety features are included to protect users during operation?

A: The machine includes an emergency stop switch, a blade cover, and LED status indicators to enhance operator safety. These features help prevent accidental injuries and allow quick response in emergency situations, ensuring workplace safety standards are maintained.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free