Photo Frame Cutting Machine

60000.00 INR/Piece

Product Details:

- Product Type FRAME CUTTING MACHINE

- General Use TO CUT FRAME RAW MATERIALS

- Material Other

- Type Other

- Capacity 4" Kg/hr

- Weight (kg) 160 Kilograms (kg)

- Computerized No

- Click to View more

X

Photo Frame Cutting Machine Price And Quantity

- 5 Piece

- 60000.00 INR/Piece

Photo Frame Cutting Machine Product Specifications

- Other

- Low Noise, Environmental Friendly, High Efficiency, Low Energy Consumption, Good Quality

- Other

- FRAME CUTTING MACHINE

- 4" Kg/hr

- 6 MONTH

- Manual

- No

- 8 INCH

- Green

- 100 Millimeter (mm)

- Semi Automatic

- N/A Microampere (A)

- Other

- 160 Kilograms (kg)

- TO CUT FRAME RAW MATERIALS

- Other

- N/A Micromete (micron)

- N/A Km/s

- No

Photo Frame Cutting Machine Trade Information

- AHMEDABAD ICD

- Western Union, Paypal, Cash on Delivery (COD), Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 100 Piece Per Month

- 15 Days

- Yes

- Contact us for information regarding our sample policy

- WOODEN PACKAGING

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- All India

- ISO 9000-2000

Product Description

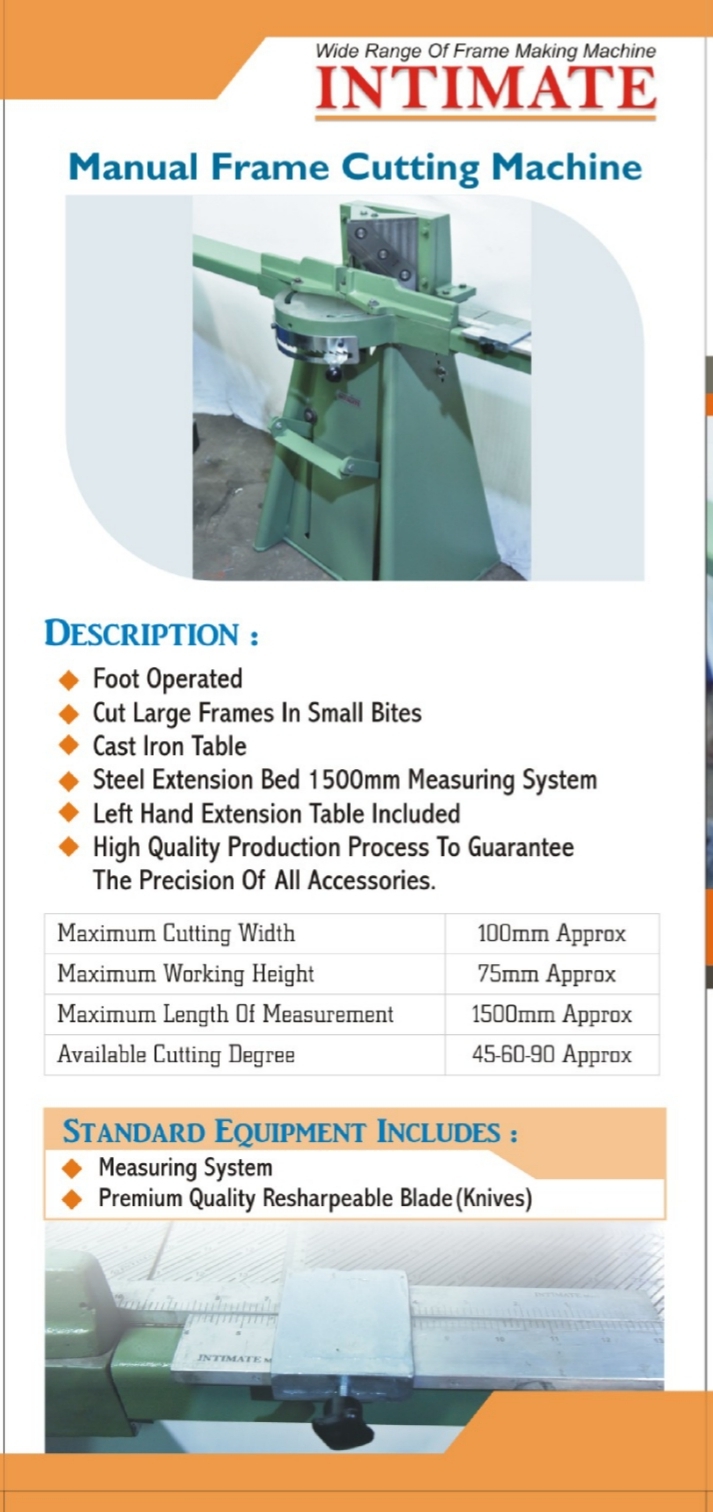

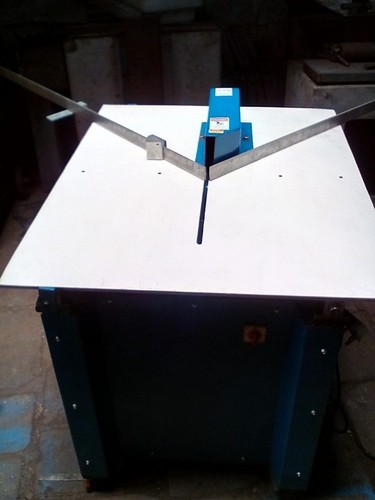

Clean, quiet, accurate and smooth cutting action.This is the professional frame cutting machine used by most framers in India. They are very reliable and long lasting-geting even better with use. It comes with sliding stop and your choice of metric or imperial scales which help you quickly set the required rebate length of the moulding.

In association with FrameMaster, we, ARA Frames supply complete range of professional framing equipments like: Frame cutting machine, foot-operated underpinners,Pnuematic underpinners, Manual and Air operated flexiguns, hardware & other accessories.

Features ofPhoto Frame Cutting Machine

- Stepwise adjustable blade block movement.

- Sliding stop and measuring scale ensuring accurate repeat work.

- Directional off-cut slide for tidy waste collection.

- Adjustable fences (45 - 90 ).

- Cuts double mitre at 45 and single mitre up to 90 .

- Adjustable rebate support holders.

- Easily cuts P. S. Mouldings and wooden mouldings.

- Weight: 110 Kgs.

| Photo Frame Cutting Machine |

|

| Product Name |

Photo Frame Cutting Machine |

| Product Code |

Photo Frame Cutting Machine |

| Place of Origin | Rajkot, Gujarat, India |

| Material |

|

| Application | Cutting Machine |

| Order Details | |

| Packaging Details | As Per Requirement |

| Delivery Time | 10 to 15 Days |

| Port | Mundra, Gujarat, India |

| Minimum Order Quantity | 1 PSC |

| Supply Ability | Any |

| Payment tearms | 50% advance |

Efficient Cutting Performance

Equipped with an 8-inch blade and a solid construction, this machine delivers high efficiency in cutting frame raw materials. The semi-automatic function enables accurate results with reduced manual effort, making it ideal for workshops and manufacturing units concerned with productivity and consistency.

Environmentally Friendly and Low Maintenance

Designed with low energy consumption and minimal noise output, this photo frame cutting machine is environmentally conscious and suitable for continuous operation. Its reliable build reduces maintenance frequency, ensuring stable performance for businesses in India.

User-Friendly Manual Control

The manual control system allows operators to easily handle the cutting process, adjusting for various thicknesses up to 100 mm. Suitable for suppliers, retailers, and traders, its engineered for smooth user experience without complications often found in computerized models.

FAQs of Photo Frame Cutting Machine:

Q: How does the manual control system work on the Photo Frame Cutting Machine?

A: The manual control system allows the operator to physically adjust and operate the machine during the cutting process, giving precise control over blade movement and pressure for different frame materials. No computerized features are involved, making operation straightforward and reliable.Q: What types of materials can the Photo Frame Cutting Machine cut?

A: This machine is designed primarily for cutting frame raw materials, including various woods and synthetic moldings. Its robust 8-inch blade and ability to cut thicknesses up to 100 mm make it suitable for a broad spectrum of standard photo frame production materials.Q: When is this cutting machine best utilized in the photo frame manufacturing process?

A: The machine is most effective during the initial stage of production, where raw frame materials require precise sizing before assembly. Its semi-automatic function and efficient cutting make it perfect for workshops seeking a balance between automation and manual input.Q: Where can you install and operate the Photo Frame Cutting Machine?

A: The Photo Frame Cutting Machine is well-suited for workshops, manufacturing floors, and retail settings across India. Its design accommodates businesses acting as exporters, manufacturers, retailers, suppliers, and traders.Q: What is the process for using the Photo Frame Cutting Machine?

A: To operate, place the raw frame material on the cutting platform, manually adjust the blade positioning, and guide the material through the cutter. The semi-automatic function aids the process, while the manual control provides accuracy for each cut. Ensure the material meets the machines 100 mm thickness limit for optimal performance.Q: What are the main benefits of using this machine for your business?

A: Key benefits include high cutting efficiency, environmentally friendly operation, low noise levels, reduced energy consumption, and high-quality results. Its 6-month warranty also offers peace of mind regarding durability and maintenance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free