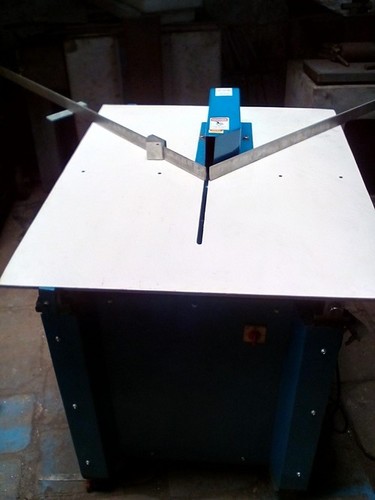

Electric Frame Cutting Machine

55000.00 - 60000.00 INR/Piece

Product Details:

- Drive Motor Heavy-duty induction motor

- Product Type Electric Frame Cutting Machine

- General Use Industrial frame production cutting

- Material Mild Steel Body with alloy blade

- Type Frame Cutting Machine

- Capacity 50-60 frames/hour

- Weight (kg) Around 120 kg

- Click to View more

X

Electric Frame Cutting Machine Price And Quantity

- 1 Piece

- 55000.00 - 60000.00 INR/Piece

Electric Frame Cutting Machine Product Specifications

- Heavy-duty induction motor

- Integrated CNC control software

- Air cooling

- Industrial frame production cutting

- Semi-automatic

- Electric motor-driven

- High precision, stable operation, easy setup

- 1200 x 700 x 1050 mm

- Green and white

- Rotary blade cutting

- 600 x 400 mm

- Straight and angular frame cutting

- 50-60 frames/hour

- Up to 15 mm (material-dependent)

- Digital panel with preset programs

- Electric Frame Cutting Machine

- 220V AC, 50Hz

- Around 120 kg

- Yes

- Mild Steel Body with alloy blade

- AC electric motor 1.5 HP

- Aluminum, wood, PVC profiles

- Adjustable, up to 60 m/min

- 0.2 mm

- Frame Cutting Machine

Electric Frame Cutting Machine Trade Information

- 100 Piece Per Month

- 10 Days

- STANDARD PACKAGING

- All India

Product Description

The FM 6 Table Cutting machine is designed and engineered with a focus on durability, reliability and safety. The blades are easily adjustable for accurate angle and pitch. Satisfying the highest production and safety standards for operation keeping hands away from the cutting area and with its completely enclosed design, no motors or blades are exposed

Features of Electric Frame Cutting Machine:

| High Production | |

| Automatic Cutting Stroke | |

| Power Saver Motor | |

| 45 Degree Measuring Scale | |

| Internal Cutting Block Support |

High-Precision Cutting Capabilities

Designed to deliver accurate frame cutting, the machine achieves mechanical precision within 0.2 mm. Its rotary cutter and automated blade feed allow for both straight and angular cuts, adapting to various requirements with ease. The digital panel and CNC software facilitate consistent, repeatable results across multiple runs, enhancing productivity and reducing wastage in industrial production.

User-Friendly Operation and Safety

Operating the machine is straightforward with push-button and touchscreen controls, supported by digital presets and CNC automation. Overload protection and an emergency stop switch ensure operator security during use, while pneumatic frame clamping and air-cooling allow for extended, uninterrupted runs. The compact design integrates effortlessly into workshop environments, with installation support available when needed.

FAQs of Electric Frame Cutting Machine:

Q: How does the Electric Frame Cutting Machine enhance cutting precision and stability?

A: It utilizes a computerized CNC control system paired with a digital panel to set programs for precise cutting. Pneumatic frame clamping and a linear automatic blade feed minimize movement during operation, ensuring consistent accuracy within 0.2 mm.Q: What materials can be cut using this machine and up to what thickness?

A: The machine is designed to cut aluminum, wood, and PVC profile materials. It can handle thicknesses up to 15 mm, depending on the materials properties.Q: When is installation service available for this frame cutting machine?

A: Professional installation services are available upon request at the time of purchase, ensuring proper setup and integration into your industrial workflow.Q: Where is the Electric Frame Cutting Machine primarily used?

A: This machine is intended for industrial use, especially in frame production workshops, manufacturing plants, and fabrication units where high-precision, high-volume frame cutting is required.Q: What is the process for operating the machine and ensuring safety?

A: Users operate the machine via a push-button or touchscreen interface, selecting preset programs for straight or angular cuts. Safety features include overload protection and an emergency stop switch, with packing provided in a robust wooden crate for secure delivery.Q: How does the machine benefit frame production operations?

A: It improves operational efficiency through semi-automatic controls, rapid adjustment of cutting speeds up to 60 m/min, and the ability to process approximately 5060 frames per hour, resulting in reduced labor time and consistent output quality.Q: What steps are involved in setting up and maintaining the equipment?

A: Setup involves connecting the machine to a 220V AC, 50Hz power source, loading frames using the pneumatic clamp, and configuring cutting parameters on the digital interface. Maintenance includes regular inspection of the blade, air cooling system, and digital controls to ensure optimal performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free