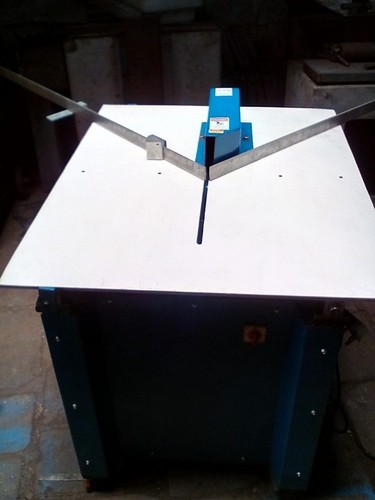

Pedal Frame Cutting Machine

Product Details:

- Product Type Pedal Frame Cutting Machine

- General Use For cutting window/door frames

- Material Heavy duty steel body

- Type Frame Cutting Machine

- Capacity 150 frames/hour

- Weight (kg) Approx 65 kg

- Computerized No

- Click to View more

Pedal Frame Cutting Machine Price And Quantity

- 1 Piece

- 60000.00 - 65000.00 INR/Piece

Pedal Frame Cutting Machine Product Specifications

- 30 cycles/min

- Integrated PLC system

- 0.5 mm

- 500 mm x 300 mm

- Industrial grey (as shown)

- Frame Cutting Machine

- For cutting window/door frames

- Heavy duty steel body

- 750 mm x 500 mm x 1100 mm

- Pedal-operated frame cutting

- No

- Air cooled

- 150 frames/hour

- Pedal Frame Cutting Machine

- Mechanical foot pedal

- Up to 6 mm (mild steel)

- Shearing with pedal force

- Manual (pedal with lever link)

- Sturdy frame construction, precision cutting, ergonomic pedal mechanism

- None (manual operation)

- Mild steel, aluminium

- 220 V AC

- Approx 65 kg

- No

Pedal Frame Cutting Machine Trade Information

- 100 Piece Per Month

- 10 Days

- STANDARD PACKAGING

- All India

Product Description

Pedal Frame Cutting Machine which is completely manual in operation which is made up by connecting the kinematic links in a desired manner to form a reliable mechanism. It works on the lever principle to cut off the frames in wood or plastic. It is capable to cut one or two angles in between the range of 45 to 90 degrees at the same time with a high class and smooth cutting surface finish. Pedal Frame Cutting Machine is provided with a position-setting unit that helps in cutting in exact length. It is very easy to use and can be controlled by a single individual for effective and good results.

This is the professional frame cutting machine used by most framers in India. They are very reliable and long lasting-geting even better with use. It comes with sliding stop and your choice of metric or imperial scales which help you quickly set the required rebate length of the moulding.

In association with Frame Master, we, intimate machine tools supply complete range of professional framing equipments like: Frame cutting machine, foot-operated underpinners,Pnuematic underpinners, Manual and Air operated flexiguns, hardware & other accessories.

Features of Photo Frame Cutter Machine

- Clean, quiet, accurate and smooth cutting action.

- Stepwise adjustable blade block movement.

- Sliding stop and measuring scale ensuring accurate repeat work.

- Directional off-cut slide for tidy waste collection.

- Adjustable fences (45 - 90 ).

- Cuts double mitre at 45 and single mitre up to 90 .

- Adjustable rebate support holders.

- Easily cuts P. S. Mouldings and wooden mouldings.

- Weight: 110 Kgs

Photo Frame Cutter Machine

| Manual Frame Cutting Machine | |

| Product Name |

|

| Product Code |

|

| Place of Origin | Rajkot, Gujarat, India |

| Material |

|

| Application | Cutting Machine |

| Order Details | |

| Packaging Details | As Per Requirement |

| Delivery Time | 10 to 15 Days |

| Port | Mundra, Gujarat, India |

| Minimum Order Quantity | 1 PSC |

| Supply Ability | Any |

| Payment terms | 50% advance |

Effortless, Accurate Cutting

Designed for manual operation, the pedal mechanism offers consistent and precise cuts with minimal effort. The rigid frame and hardened alloy steel blade minimize vibration and deliver high-quality, repeatable results. This machine is an excellent solution for manufacturing window and door frames, accommodating mild steel and aluminum profiles.

Simple, Safe, and Reliable Operation

With a fully mechanical drive, theres no need for electrical connectionssimply position the machine and start cutting. The integrated safety guard and ergonomic pedal design prioritize user safety, making it accessible and straightforward for operators of any experience level. Maintenance is minimal, and blade changes are simple.

Built for Demanding Environments

Engineered to withstand humid workshop conditions, the pedal frame cutting machine features a tough, powder-coated finish for corrosion protection. Manual oiling points are easy to access, ensuring smooth operation and longevity. Its heavy-duty construction and sturdy performance make it an ideal choice for exporters, manufacturers, and suppliers.

FAQs of Pedal Frame Cutting Machine:

Q: How does the pedal frame cutting mechanism operate without electricity?

A: The machine is fully mechanical, powered by an ergonomic foot pedal linked to a lever system. When pressed, the pedal activates the hardened alloy steel blade for cutting. No electrical connections are needed, providing immediate plug-and-use convenience.Q: What materials and thicknesses can be cut with this machine?

A: This pedal frame cutting machine is designed to cut mild steel and aluminum frames up to 6 mm in thickness. It is particularly suitable for window and door frame fabrication using these metals.Q: When is this type of manual cutting machine most beneficial?

A: It is especially advantageous in workshops where electrical power is unreliable or unavailable, or where portability is required. The machines sturdy design and manual operation offer dependable performance in both small and large-scale frame production.Q: Where can the machine be installed and used effectively?

A: Thanks to its robust, powder-coated, humidity-resistant construction, the machine is well-suited for use in a wide variety of industrial and manufacturing environments, including those with higher moisture levels or limited power supply.Q: What maintenance steps are required for optimal operation?

A: Routine maintenance includes manual oiling at designated points and periodic blade replacement, which is designed to be quick and easy. The machines simple construction means low maintenance costs and minimal downtime.Q: How does the integrated safety guard enhance user safety?

A: The built-in safety guard helps protect operators from accidental contact with the cutting blade, reducing the risk of injury during operation and making the process safer for all users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free