Drum Sander Machine

375000.00 - 550000.00 INR/Piece

Product Details:

- Operating Temperature 0-45C

- Noise Level Below 78 dB

- Lubricating System Manual Grease Lubrication

- Drive Belt Drive

- Frame Type Steel Welded

- Voltage 415 V

- Features Heavy-duty frame, user-friendly control, fast sanding change

- Click to View more

X

Drum Sander Machine Price And Quantity

- 375000.00 - 550000.00 INR/Piece

- 1 Piece

Drum Sander Machine Product Specifications

- 0-45C

- Modern Belt-driven

- Manual Grease Lubrication

- Below 78 dB

- Steel Welded

- Belt Drive

- 2.2 kW

- Heavy-duty frame, user-friendly control, fast sanding change

- Adjustable up to 5 Bar

- Green & White

- 415 V

- Drum Sander Machine

- 500 ft/hr

- Woodworking Drum Sander

- Electric

- 1250 x 700 x 950 mm

- Switch Panel

- Wood sanding, finish sanding panels, furniture

- 3 HP Induction Motor

- 50 Hz

- Air cooled

- No digital connectivity

- DS-400

- Approx. 210 kg

- 3 HP

- Powder Coated

- Semi-Automatic

- 0.1 mm

Drum Sander Machine Trade Information

- 100 Piece Per Month

- 10 Week

- STANDARD PACKAGING

- All India

Product Description

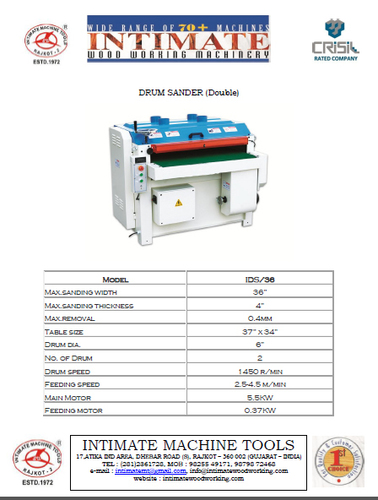

Drum Sander

Product details

| Frequency | 50 Hz |

| Brand | Intimate |

| Weight Of Machine | 400 Kg Approx |

| Voltage | 240 V |

| Sanding Drum Diameter | 125 mm |

| Power Source | Electric |

| Phase | Three Phase |

| Maximum Sanding Thickness | 150 mm |

Optimal Performance with Precision Control

The DS-400 Drum Sander combines a heavy-duty steel welded frame with efficient belt-driven technology to deliver high-quality sanding at a capacity of 500 ft/hr. Adjustable pressure up to 5 Bar and a precision ground steel work table guarantee excellent smoothness and operational consistency for varying wood types and thicknesses.

Safety and User Convenience

Special features such as an enclosed drum guard, emergency stop button, and user-friendly switch panel ensure safe operation. Maintenance is simplified by easy-access panels and manual grease lubrication, while the semi-automatic conveyor minimizes manual labor, making the machine suitable for both skilled technicians and novice users.

Versatile Applications in Woodworking

This drum sander is ideal for sanding panels, preparing furniture surfaces, and fine finish work. Its broad grit range (60-320) and precise feed system make it a reliable solution for manufacturers, exporters, and retailers seeking supreme finish quality for their wood products.

FAQs of Drum Sander Machine:

Q: How does the DS-400 Drum Sander ensure a high-quality finish on wood surfaces?

A: The machine uses precision ground steel work tables, adjustable sanding pressures up to 5 Bar, and supports a sandpaper grit range of 60 to 320. These features work together to deliver consistent smooth finishes for various wood types and dimensions.Q: What is the maximum sanding width and thickness the Drum Sander Machine DS-400 can handle?

A: The DS-400 can sand materials up to 400 mm in width and up to 100 mm in thickness, making it suitable for large panels and thick furniture pieces.Q: When is installation service available for this drum sander machine?

A: Installation service is available on request for customers, ensuring the machine is professionally set up and optimized for operation in your workshop or facility.Q: Where is the DS-400 Drum Sander typically used?

A: This machine is widely used in woodworking workshops, furniture manufacturing units, and panel finishing operations, particularly by exporters, retailers, and suppliers across India.Q: What is the process for changing sandpaper on the DS-400?

A: Sandpaper changes are fast and straightforward thanks to the user-friendly design and easy-access maintenance panels, minimizing downtime and keeping productivity high.Q: How is safety addressed in the operation of this drum sander?

A: Safety is prioritized with an enclosed drum guard, emergency stop function, and a secure switch panel, protecting operators during use and maintenance.Q: What are the benefits of using the DS-400 Drum Sander for your wood sanding needs?

A: Users benefit from high smoothness, semi-automatic operation, efficient dust collection (100 mm diameter port), easy maintenance, and heavy-duty construction, ensuring reliable performance and precise results for various woodworking applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free