Belt And Disc Sander Machine

Product Details:

- Voltage 220 V

- Accuracy High Precision Finish

- Frequency 50 Hz

- Power Rating 0.5 HP

- Model No BD370

- Lubricating System Sealed Bearings

- Production Capacity Multiple Units/Hour

- Click to View more

Belt And Disc Sander Machine Price And Quantity

- 24000.00 - 36000.00 INR/Piece

- 1 Piece

Belt And Disc Sander Machine Product Specifications

- 0.5 HP

- 50 Hz

- High Precision Finish

- 220 V

- 370 W

- Multiple Units/Hour

- Sealed Bearings

- BD370

- Powder Coated

- Sanding, smoothing, and finishing of wood, metal, and plastics

- Blue & Silver

- Belt and Disc Sander Machine

- <80 dB

- 370 W

- Direct Drive

- Advanced Abrasive Sanding

- Electric

- Bench Grinder/Sander

- 22 kg

- Cast Iron

- Manual Switch

- 5C to 40C

- Air Cooled

- 500 x 300 x 350 mm

Belt And Disc Sander Machine Trade Information

- 100 Piece Per Month

- 10 Days

- STANDARD PACKAGING

- Australia, Eastern Europe, Middle East, Africa, Central America, South America, Western Europe, Asia, North America

- All India

Product Description

Providing our customers with superior quality of Belt & Disc Sanders which are used to smooth the wood surface. The machine is widely acknowledged for its high performance coupled with reliable service. It is quite durable and sturdy as it is manufactured from superior quality raw material hence it is anti corrosive as well. We offer these Belt & Disc Sanders at really affordable prices. Our customers can also avail from us different models to meet various demands.

Specifications :

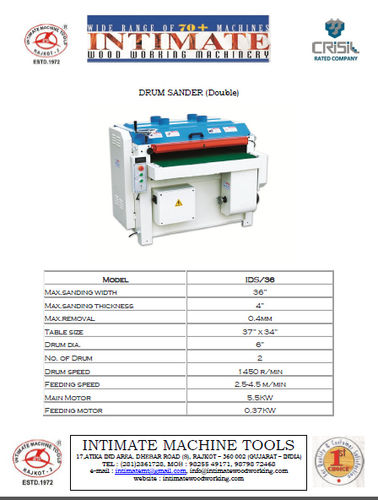

| Model No. | IBDS/36 | IBDS/48 | IDBS/60 | IDBS/72 |

| Belt Width | 6" | 6" | 6" | 6" |

| Belt Length | 36" | 48" | 60" | 72" |

| Disc Dia | 10" | 12" | 15" | 18" |

| Belt Sanding Table (Horizontal & Vertical) | 6" X 8" | 6" X 14" | 6" X 20" | 6" X 25" |

| Disc Sanding Table | 20" X 7" | 20" X 7" | 25" X 9" | 25" X 9" |

| Disc Table Tilt | To Left 45o | To Left 45o | To Left 45o | To Left 45o |

| Speed Of Belt Pulley | 383 mt./min | 383 mt./min | 383 mt./min | 383 mt./min |

| Power required HP/RPM | 1/1440 | 1/1440 | 1.5/1440 | 2/1440 |

Efficient & Versatile Performance

The BD370 Belt and Disc Sander delivers robust and consistent sanding with high precision across wood, metal, and plastics. Its 370 W direct drive motor and multiple units/hour production capability make it a versatile addition to any workshop, providing professional-quality results for a range of applications.

Sturdy Construction & Advanced Features

Constructed from cast iron and treated with a powder-coated finish, the BD370 ensures enhanced stability and durability. Advanced features like air cooling, sealed bearings, and a noise level below 80 dB guarantee smooth operation, even during prolonged use in challenging environments.

User-Friendly Control & Maintenance

This machine is designed for ease of use with a manual switch control system and minimal maintenance requirements, thanks to sealed bearings. The air-cooled system keeps the motor operating at optimal temperature, allowing for efficient and continuous sanding with little downtime.

FAQs of Belt And Disc Sander Machine:

Q: How does the BD370 Belt and Disc Sander ensure a high-precision finish?

A: The BD370 utilizes advanced abrasive sanding technology combined with direct drive transmission, which offers stable speed and torque. This, together with high-quality abrasive belts and discs, results in a consistently smooth and accurate finish across different materials.Q: What materials can I sand using this machine and what are its primary applications?

A: This sander is designed for sanding, smoothing, and finishing wood, metal, and plastics, making it suitable for various applications such as furniture making, metalworking, and plastic fabrication in workshops and manufacturing units.Q: Where is the BD370 commonly installed or used?

A: Typically, the BD370 is installed on a workbench in woodworking or metalworking shops, industrial manufacturing plants, or maintenance workshops. Its compact size and manageable weight make it ideal for both small and large-scale work environments.Q: What is the process for operating the sander safely and efficiently?

A: First, ensure the machine is placed on a stable surface and connected to a 220 V power supply. Turn on the manual switch, select the appropriate abrasive belt or disc for your material, and guide the workpiece evenly across the surface. Always wear appropriate safety gear while operating.Q: When should I perform maintenance on the sander and what does it entail?

A: Regular maintenance involves checking the abrasive surfaces for wear, cleaning dust from the unit, and inspecting the sealed bearings. Thanks to the air-cooled and sealed bearing systems, maintenance is minimal and can usually be done after several hours of operation or as needed.Q: What are the benefits of the air-cooled and sealed bearing systems in this sander?

A: The air-cooled system prevents overheating during long periods of operation, while sealed bearings ensure smooth, efficient movement and protect against dust and debrisresulting in longer machine life and reduced need for frequent servicing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free