Wide Belt Sander Machine

Product Details:

- Machine Type Wide Belt Sander

- Operating Temperature 5C - 40C

- Features High precision sanding, adjustable working speed, digital thickness control, emergency stop, anti-vibration base

- Frequency 50 Hz

- Cooling System Air cooled

- Noise Level <85 dB

- Accuracy 0.05 mm

- Click to View more

Wide Belt Sander Machine Price And Quantity

- 1 Piece

- 1150000 INR/Piece

Wide Belt Sander Machine Product Specifications

- Digital microprocessor based

- 10 HP

- Heavy Duty Welded Steel Frame

- Automatic Centralized Lubrication

- Wide Belt Sander Machine

- 0.05 mm

- 2200 x 1300 x 1900 mm

- Grey/Blue

- WBS-1300

- Powder Coated

- 380V / 415V AC

- 7.5 kW

- Approx. 1350 kg

- Variable (depends on material and feed rate)

- Belt Drive

- Advanced Sanding Technology

- Adjustable (as per material requirements)

- Wide Belt Sander

- 50 Hz

- 10 HP

- High precision sanding, adjustable working speed, digital thickness control, emergency stop, anti-vibration base

- 5C - 40C

- <85 dB

- Semi-Automatic

- Air cooled

- Wood and board surface sanding, door and panel finishing, furniture making

- Electric

Wide Belt Sander Machine Trade Information

- 100 Piece Per Month

- 10 Days

- STANDARD PACKAGING

- Eastern Europe, Middle East, Africa, Central America, Australia, South America, Western Europe, Asia, North America

- All India

Product Description

Wide Belt Sander Machine is a heavy duty industrial machinery which is used for the sanding and planning of the woods at the same platform. It is provided with an extra-large cutter head which is manufactured by using alloyed materials with high precision and dimensional accuracy. The system is provided with an anti-kickback fingers unit which acts as a safety guard for the operator. Wide Belt Sander Machine is provided with electronic control unit which makes it very easier to control various machining parameters. It provides maximum cutting stability and excellent surface cut and is also provided with limit switches which helps in the prevention of the damage to the machines in case of mistracking and breaking of the bel.

|

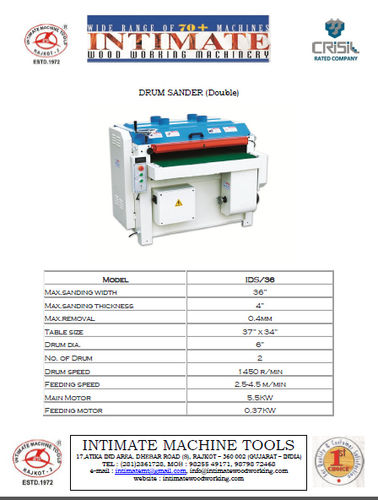

MODEL |

|

|

Working width |

40-1300mm |

|

Working thickness |

3-100mm |

|

Working length min. |

600mm |

|

Feed speed |

6-30/min |

|

Size of sand belt |

1330x2200mm |

|

Main motor power |

22kw, 11kw |

|

Total motor power |

37.74kw |

|

Volume of sucked air |

90m3/hr |

|

Overall size |

2360x2030x2220mm |

Advanced Precision and Efficiency

This sander integrates advanced sanding technology and a digital microprocessor-based control system for precise thickness adjustment and consistent surface quality. With an adjustable working speed from 6 to 30 m/min, it adapts smoothly to various materials and finishing requirements, supporting flexible production needs.

Safety and Maintenance Simplified

Featuring an integrated emergency stop, safety interlock, and overload protection, operator safety is firmly ensured. Low-maintenance design with easy-access service points and automatic lubrication prolongs machine life and reduces downtime. The air-cooled system and anti-vibration base contribute to dependable, quiet operation.

Versatile Applications and Support

Optimized for various applications such as door and panel finishing, furniture making, and board surface calibration, this sander delivers variable production capacitydetermined by material and feed rate. Onsite and remote service support assist users across India, ensuring smooth operation and quick issue resolution.

FAQs of Wide Belt Sander Machine:

Q: How do I adjust the working speed and pressure for different materials on the Wide Belt Sander WBS-1300?

A: The machine offers variable working speed from 6 to 30 m/min and adjustable pressure rollers. You can modify these settings using the digital microprocessor control panel for optimal sanding results on materials such as solid wood, MDF, and veneers.Q: What is the process for routine maintenance on the Wide Belt Sander?

A: Routine maintenance involves checking the sanding belt, cleaning the dust collection ports, and inspecting the rubber-coated segmented rollers. The automatic centralized lubrication and easy-access service doors simplify regular upkeep, helping ensure consistent machine performance.Q: When should I use the emergency safety device during operation?

A: The integrated emergency stop and safety interlock should be activated instantly if any unsafe or irregular machine behavior occurs. These devices help prevent accidents and quickly shut down the sander in critical situations.Q: Where is the Wide Belt Sander WBS-1300 best used?

A: This sander is ideal for industrial settings, furniture manufacturing facilities, woodworking shops, and panels or door finishing lines. Its robust build and dependable performance suit high-volume production environments across India.Q: What benefits does the digital thickness control offer?

A: Digital thickness control provides exceptional accuracy (0.05 mm) and repeatability, ensuring consistent surface sanding and reducing errors across multiple workpieces. This improves quality and minimizes material waste.Q: How does the dust collection system enhance the sanding process?

A: The 150 mm diameter dust collection port efficiently removes sanding debris, promoting a cleaner workspace and improved air quality. This system helps prolong machine life and supports superior finishing results.Q: What support and assistance are available for Wide Belt Sander users in India?

A: Users benefit from both onsite and remote service assistance, including installation help, troubleshooting, and maintenance guidance. This ensures quick resolution of technical issues and maximizes machine uptime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free