Edge Sander Machine

24000.00 - 36000.00 INR/Piece

Product Details:

- Power Rating 1.5 kW

- Noise Level Below 80 dB

- Frequency 50 Hz

- Cooling System Natural Air Cooled

- Features Tiltable sanding belt, table adjustment, robust build, dust extraction port

- Frame Type Heavy Duty Fabricated Frame

- Model No ES-2200

- Click to View more

X

Edge Sander Machine Price And Quantity

- 1 Piece

- 24000.00 - 36000.00 INR/Piece

Edge Sander Machine Product Specifications

- Edge sanding of wood, plywood, and MDF panels in furniture and carpentry workshops

- Edge Sander

- Manual Controls

- Continuous Operation

- 5C to 45C

- Edge Sander Machine

- 2 HP

- Standard Shop Air Pressure

- 220-380 V

- 2200 x 900 x 1200 mm

- 0.2 mm

- Conventional Mechanical Sanding

- Electric

- Green & White

- Belt Drive

- Manual Grease Points

- ES-2200

- 2 HP

- Paint Coated

- Heavy Duty Fabricated Frame

- Semi Automatic

- Approx. 250 kg

- Tiltable sanding belt, table adjustment, robust build, dust extraction port

- Natural Air Cooled

- 50 Hz

- 1.5 kW

- Below 80 dB

Edge Sander Machine Trade Information

- 100 Piece Per Month

- 10 Days

- STANDARD PACKAGING

- All India

Product Description

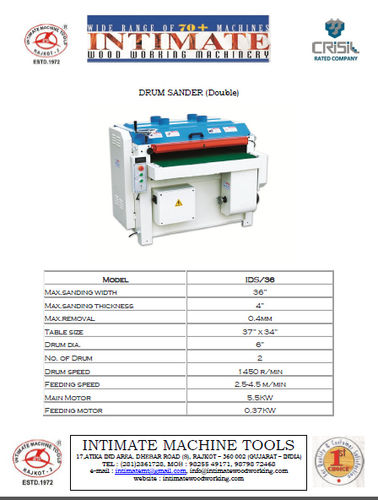

Specification

| Model No. | Iedgs/72 |

| Blet Size | 6 X 72 |

| Max. Sanding Width | 6 X 25 |

| Power Req Hp/Rpm | 1.5/1440 |

Product details

| Belt Size | 6 x 72 inch |

| Brand | Intimate |

| Power | 5 HP |

| Speed | 1440 RPM |

| Power Source | Electric |

| Model No | IEDGS/72 |

| Max Sanding Width | 6 x 25 inch |

Robust and Adjustable Sanding Performance

The ES-2200 Edge Sander is designed to enable seamless edge sanding with high precision. Its wide tiltable belt and spacious work table make it ideal for handling diverse panel sizes and profiles. The manual table up-down adjustment provides enhanced control, while the machines engineered heavy-duty frame ensures steady, vibration-free operation even during continuous use in demanding workshop environments.

Safety and Dust Management Features

This edge sander prioritizes operator safety and workplace cleanliness. The built-in emergency stop switch and belt guard minimize risk during operation, while the integrated dust collection port (100 mm diameter) connects easily to standard shop extraction systems, reducing airborne particles and maintaining a healthier workspace. Maintenance is straightforward, aided by manual grease lubrication points and accessible spare parts supply.

FAQs of Edge Sander Machine:

Q: How do I adjust the sanding belt angle on the ES-2200 Edge Sander?

A: The sanding belt angle range can be manually adjusted from 0 to 90, allowing you to set precise angles for different edge finishing requirements. Use the adjustment mechanism provided to tilt the belt securely before powering on the machine.Q: What types of materials can be processed with this edge sander?

A: The machine is suitable for sanding wood, plywood, and MDF panels, making it highly versatile for furniture production and carpentry tasks.Q: When should I perform maintenance on the ES-2200, and what does it involve?

A: Routine maintenance includes regular lubrication through manual grease points, cleaning the dust extraction port, and checking belt condition. Schedule maintenance monthly or after intensive use for optimal performance.Q: Where should the machine be installed for best results?

A: Install the ES-2200 on a solid, level floor in your workshop to ensure stability. Its floor-mounted design minimizes vibration and maximizes safety during operation.Q: What is the process for adjusting the working table height?

A: The table is adjusted manually up and down, allowing convenient setting to accommodate different panel thicknesses. Use the provided handles or levers to raise or lower the table before starting your sanding job.Q: How does the dust collection system benefit my workspace?

A: The 100 mm dust collection port efficiently extracts sanding debris when connected to a shop dust extractor. This feature helps keep your environment cleaner and improves air quality, reducing maintenance effort.Q: What after-sales service and spare parts support does the manufacturer offer?

A: The manufacturer provides after-sales support and spare parts supply upon request. You may contact them directly for service assistance or to order replacement components, ensuring longevity and effective operation of your machine.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free