Double Disc Sander Machine

45000.00 - 130000.00 INR/Piece

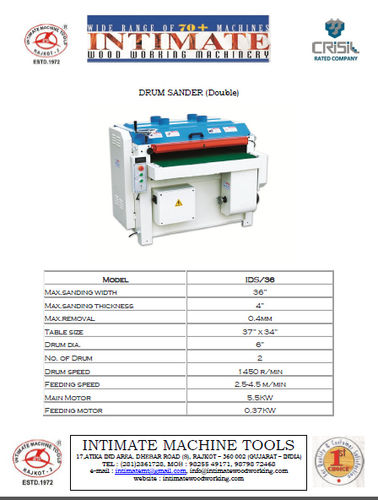

Product Details:

- Machine Type Double Disc Sander

- Control System Switch Control

- Features Dust Extraction Port, Robust Construction, Heavy Duty Base

- Frequency 50 Hz

- Power Rating 1.1 kW

- Accuracy High Precision Sanding Finish

- Frame Type Heavy Cast Iron Frame

- Click to View more

X

Double Disc Sander Machine Price And Quantity

- 45000.00 - 130000.00 INR/Piece

- 1 Piece

Double Disc Sander Machine Product Specifications

- Standard workshop air pressure (manual feed)

- Approx. 100 kg

- No smart connectivity

- Below 82 dB

- Blue / Grey

- Powder Coated/Polished

- Switch Control

- Manual

- Dust Extraction Port, Robust Construction, Heavy Duty Base

- Air Cooled Motor

- Approx. 850 x 450 x 1100 mm

- Electric

- Suitable for small to medium workshops

- 1.5 HP / 1.1 kW

- Heavy Cast Iron Frame

- Double Disc Sander

- High Precision Sanding Finish

- 1.1 kW

- Surface finishing, deburring, smoothing, and sanding of wood, metal, plastics

- 50 Hz

- Double Disc Sander Machine

- 1.5 HP

- Abrasive Belt & Disc Sander

Double Disc Sander Machine Trade Information

- Cheque, Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash Advance (CA)

- 100 Piece Per Month

- 10 Days

- STANDARD PACKAGING

- All India

Product Description

We are among the leading manufacturers and exporters of qualitative range of Double Disc Sander. Woodworking is aided with this machine at large scale. These are designed at our well equipped infrastructure using premium quality raw materials and components that are sourced from the most credible vendors of the market. These disc sanders are accessible by the customers from us in different capacities and specifications as per the wide requirements. Double Disc Sander is double checked for quality after production, to assure clients of high quality at our end.

Features of Double Disc Sander:

-

Robust construction

-

Unobstructed hassle free operations

-

Low maintenance

High Precision Surface Treatment

Achieve consistently smooth, professional results on wood, metal, and plastic surfaces. The Double Disc Sander ensures a high precision finish suitable for fine craftsmanship or industrial applications. Powered by a 1.5 HP motor, it delivers ample torque for demanding tasks, whether youre deburring, smoothing, or preparing material for further processing.

Designed for Durability and Safety

Constructed with a robust heavy cast iron frame, the sander boasts a stable operating base and a powder-coated or polished exterior for lasting protection. The built-in dust extraction port enhances workshop cleanliness, while the low-noise air-cooled motor keeps noise levels below 82 dB, creating a safe and comfortable environment for extended use.

FAQs of Double Disc Sander Machine:

Q: How does the Double Disc Sander Machine operate?

A: The Double Disc Sander Machine operates on electric power, using an air-cooled 1.5 HP motor. It features manual feed, requiring the user to manually guide the workpiece against the abrasive discs for sanding, deburring, or finishing tasks. The switch control system offers straightforward on/off operation, while standard shop air pressure assists in pressure regulation.Q: What materials can be processed using this sander?

A: This machine is suitable for surface treatment of various materials, including wood, metal, and plastics. Its abrasive technology enables efficient smoothing, deburring, and fine finishing across a diverse range of industrial and workshop applications.Q: When should I consider using a double disc sander instead of a single disc sander?

A: Consider using a double disc sander when you require higher productivity, uniform surface finishing, or need to handle diverse materials in succession. The double-disc design allows for simultaneous processing or quick changeovers between tasks, making it ideal for small to medium workshops with varied demands.Q: Where can the Double Disc Sander Machine be installed?

A: With dimensions of approximately 850 x 450 x 1100 mm and a weight around 100 kg, this sander fits well in small to medium workshop spaces. Its heavy-duty base and frame ensure stable placement on workshop floors, and it operates best where standard electric supply and air pressure are available.Q: What is the process for routine maintenance of this machine?

A: Routine maintenance involves regularly checking and cleaning the dust extraction port, ensuring the abrasive discs and belts are in good condition, and inspecting the motor and switch controls for any wear. The powder-coated or polished surfaces can be wiped down to prevent corrosion, ensuring lasting performance.Q: How does the machine benefit my workshop operations?

A: This double disc sander enhances productivity through its reliable performance, high precision finish, and efficient material removal. The robust construction and dust management features contribute to a safer, cleaner workspace, supporting both quality output and operator well-being.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free