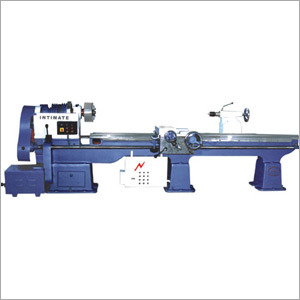

Semi Automatic Spiral Lathe

Product Details:

- Product Type Semi Automatic Spiral Lathe

- Machine Type Lathe Machine

- Machine Style Spiral Cutting

- Capacity Heavy Duty

- Power 5.5 kW

- Automation Semi Automatic

- Motor Induction Motor

- Click to View more

Semi Automatic Spiral Lathe Price And Quantity

- 325000.00 - 550000.00 INR/Piece

- 1 Piece

Semi Automatic Spiral Lathe Product Specifications

- 2500 x 1100 x 1450 mm

- Semi Automatic Spiral Lathe

- Induction Motor

- 1950 kg

- Heavy Duty

- Spiral Cutting

- 1440 RPM

- 5.5 kW

- Lathe Machine

- Semi Automatic

Semi Automatic Spiral Lathe Trade Information

- 100 Piece Per Month

- 10 Days

- STANDARD PACKAGING

- Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- All India

Product Description

Available in different models to cater various needs of our customers, these Semi Automatic Spiral Lathe machines are used in wood working industry. These machines are highly praised due to their ability to consume less power which in turn saves cost. Our Semi Automatic Spiral Lathe machine is known for its durability, high performance and reliability. We offer these machines at really affordable prices.

Specifications of Semi Automatic Spiral Lathe Machine:

| Model No. | IWL - 275 | IWL - 305 | IWL 365 |

| Working capacity of between center | 4.5 ft. | 5.5 ft. | 7.5 ft. |

| Max dia of turning | 12" | 12" | 12" |

| Max length of worm | 30" | 30" | 30" |

| Min length of worm | 1" | 1" | 1" |

| Max tapper turning/ length | 4" / 4.5 ft. | 4" / 5.5 ft. | 5" X 7.5 ft. |

| Power required HP | 4 | 4 | 4 |

Optimized for Heavy-Duty Spiral Cutting

This semi-automatic spiral lathe is engineered specifically for heavy-duty operations that require consistent spiral cutting. With its powerful 5.5 kW induction motor and precisely balanced structure, users can expect high-quality, accurate results in demanding production environments.

User-Friendly Operation with Semi-Automatic Control

Combining the efficiency of automation with the flexibility of manual control, the semi-automatic spiral lathe allows operators to manage and monitor the cutting process with ease. The interface is designed for straightforward usage, minimizing training time and maximizing productivity.

FAQs of Semi Automatic Spiral Lathe:

Q: How does the semi-automatic spiral lathe operate?

A: The semi-automatic spiral lathe combines automatic controls for certain processes with manual intervention for others. This allows operators to adjust settings as needed while the machine handles key spiral cutting operations, ensuring both precision and flexibility.Q: What are the main benefits of using this lathe for spiral cutting?

A: The main benefits include high stability during heavy-duty cutting, consistent accuracy thanks to the 5.5 kW induction motor and 1440 RPM speed, and a semi-automatic design that makes the process both efficient and adaptable to various tasks.Q: When should I choose a semi-automatic spiral lathe over a fully automatic one?

A: A semi-automatic spiral lathe is best suited when you require a balance between manual control and automation. Its ideal for operations needing frequent adjustments or custom spiral patterns, without sacrificing speed or precision.Q: Where is this spiral lathe manufactured and available for purchase?

A: This machine is manufactured in India and is available through exporters, manufacturers, retailers, suppliers, and traders. It can be procured both domestically and for international export.Q: What is the recommended process for using this heavy-duty spiral lathe?

A: Begin by securing the workpiece, selecting the desired spiral pattern, and setting operational parameters. Monitor the semi-automatic cutting process closely, making manual adjustments as necessary to maintain precision and safety throughout the job.Q: How can this lathe improve production efficiency in my workshop?

A: By automating repetitive aspects of spiral cutting while allowing operator oversight, the semi-automatic lathe minimizes errors and downtime, thus boosting throughput and overall productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free