Multi Boring

350000.00 INR

Product Details:

- Product Type Multi Boring Machine

- Machine Type Woodworking Machine

- Machine Style Horizontal and Vertical Boring

- Capacity High output, suitable for mass production

- Voltage 380 V

- Power 3.7 kW

- Automation Semi-Automatic

- Click to View more

X

Multi Boring Price And Quantity

- 1 Piece

- 350000.00 INR

Multi Boring Product Specifications

- Horizontal and Vertical Boring

- High output, suitable for mass production

- 380 V

- Multi Boring Machine

- 2800 RPM

- Woodworking Machine

- 3.7 kW

- 1000 kg

- Semi-Automatic

- Robust electric motor

- Standard industrial color (Blue/Grey)

- 2600 mm x 1100 mm x 1500 mm

Multi Boring Trade Information

- 100 Piece Per Month

- 10 Days

- STANDARD PACKAGING

- All India

Product Description

Multi Boring

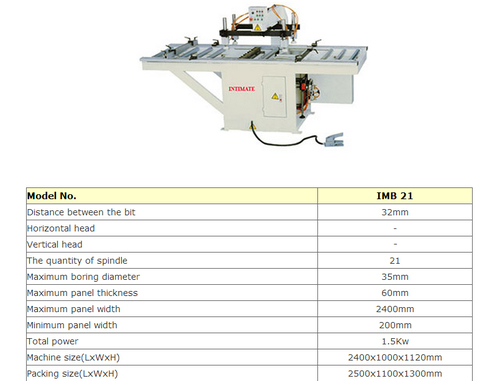

| Model No. | IMB 21 |

| Distance between the bit | 32mm |

| Horizontal head | - |

| Vertical head | - |

| The quantity of spindle | 21 |

| Maximum boring diameter | 35mm |

| Maximum panel thickness | 60mm |

| Maximum panel width | 2400mm |

| Minimum panel width | 200mm |

| Total power | 1.5Kw |

| Machine size(LxWxH) | 2400x1000x1120mm |

| Packing size(LxWxH) | 2500x1100x1300mm |

Adaptable Drilling Solutions

With up to 21 configurable drilling heads, this machine offers exceptional flexibility for complex boring patterns and high-volume production. Its horizontal and vertical boring styles suit both modular cabinetry and panel furniture manufacturing, ensuring precise and rapid processing for diverse project needs.

Efficient and User-Friendly Operation

The Multi Boring Machine combines manual and pneumatic clamping with intuitive control systems including toggle switches and dials. These features simplify setup and adjustment, promoting safety and ergonomic workflow. Adjustable work tables accommodate a wide range of workpiece sizes, ensuring seamless operation and increased productivity.

Built for Durability and High Output

Equipped with a robust electric motor powering 21 drilling heads at 2800 RPM, this heavy-duty machine stands up to demanding industrial environments. Its long-lasting construction, quick-change chuck system, and high output capacity make it a preferred choice for manufacturers and traders seeking reliable, continuous performance.

FAQs of Multi Boring:

Q: How does the Multi Boring Machine handle different workpiece sizes?

A: The adjustable heavy-duty work table allows operators to process workpieces ranging from 150 mm to 2550 mm in length, making it suitable for a wide array of woodworking projects.Q: What materials can be used with this machine?

A: The machine is compatible with plywood, MDF, particle board, and solid wood, providing versatility for various furniture and cabinetry manufacturing applications.Q: When is manual clamping preferred over pneumatic clamping?

A: Manual clamping offers direct control in delicate or customized jobs, while pneumatic clamping is ideal for quick setup and repetitive tasks, enhancing efficiency and throughput in mass production.Q: Where is the Multi Boring Machine typically installed?

A: This machine is engineered for industrial settings such as furniture factories, woodworking workshops, and modular cabinetry production lines due to its high capacity and robust design.Q: What is the process for changing drilling tools?

A: Tool change is simplified by the quick-change chuck system, enabling rapid replacement or adjustment of drills without significant downtime, supporting efficient workflow on varied projects.Q: How does the control system benefit operators?

A: Operators benefit from the straightforward toggle switches and dials, which allow for quick adjustment and ensure user-friendly control during machine setup and operation.Q: What are the advantages of the machines noise level and operating temperature range?

A: With noise levels at or below 80 dB and an operating temperature range from 5C to 45C, the machine ensures a comfortable working environment and reliability across diverse workshop conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free