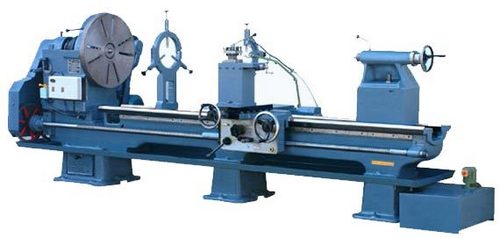

Heavy Duty Lathe Machine

Product Details:

- Product Type Heavy Duty Lathe Machine

- Cutting Thickness Up to 25 mm

- Control System Manual

- Max. Swing Diameter 660 mm

- Voltage 415 V, 3 Phase

- Weight (kg) 2500 kg

- Dimension (L*W*H) 3200 x 1200 x 1450 mm

- Click to View more

Heavy Duty Lathe Machine Price And Quantity

- 1 Piece

- 140000.00 INR/Piece

Heavy Duty Lathe Machine Product Specifications

- Robust Construction, Precision Spindle, Hardened Bed

- 415 V, 3 Phase

- Industrial Green & Silver

- Manual

- High

- Up to 25 mm

- 2500 kg

- 3200 x 1200 x 1450 mm

- Heavy Duty Lathe Machine

- 660 mm

Heavy Duty Lathe Machine Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 100 Piece Per Month

- 10 Days

- STANDARD PACKAGING

- All India

Product Description

Heavy Duty Lathe Machine is a popular metal fabrication machinery which is used in every metalworking industry for the production of top quality mechanical components and tools. It is large in sizes and having a rigid construction which ensures larger service life. It works by removing metal from a piece of work to transform it into a desired shape and size by forcing the rotating work part against the tool which in turn chips off the material. Heavy Duty Lathe Machine is provided with a large number of high performance component parts such as chuck, spindle, carriage, lead screw, feed rod, hand wheel, tailstock etc. that are mounted on a rigid bed. It can be used to perform different operations such as cutting, turning, knurling and various other processes.

Robust Construction for Demanding Environments

Built with industrial-grade materials and a hardened bed, this lathe ensures durability and reliability during prolonged usage, even under heavy workloads. Its solid build reduces vibration, aiding in precise machining and long-term operational stability.

Precision & Flexibility in Machining

The lathes precision spindle and generous max swing diameter of 660 mm enable machining of a wide range of components with accuracy. The machines substantial capacity makes it ideal for both large and detailed workpieces, adapting to diverse operational needs.

FAQs of Heavy Duty Lathe Machine:

Q: How do I operate the Heavy Duty Lathe Machines manual control system?

A: The machine is designed with an intuitive manual control panel, allowing operators to adjust speeds and feeds precisely for various turning applications. Proper training and adherence to safety protocols are recommended for optimal performance.Q: What materials can this lathe machine cut, and up to what thickness?

A: This lathe is suitable for a variety of metals and alloys, able to handle cutting thicknesses of up to 25 mm. Its heavy-duty design supports robust machining for industrial-scale projects.Q: When should I choose this Heavy Duty Lathe for my fabrication shop?

A: Opt for this lathe when you require high-capacity performance, precise turning, and rugged reliability for heavy and continuous operations. Its advanced features and stability make it ideal for fabrication shops, repair facilities, and manufacturing plants.Q: Where can I install the Heavy Duty Lathe Machine?

A: Given its dimensions (3200 x 1200 x 1450 mm) and weight (2500 kg), this machine is best installed in spacious, industrial environments with reinforced flooring and access to a 415 V, 3-phase power supply.Q: What is the process for ordering and installation if I am based in India?

A: We are an exporter, manufacturer, supplier, trader, and retailer across India. Contact us for a quotation; we assist with transportation, installation, and setup to ensure seamless integration into your workshop.Q: How is the robust construction of the lathe advantageous for users?

A: The machines solid steel build, hardened bed, and precision components minimize vibration, enhance accuracy, and extend the lifespan of the equipment, directly benefiting productivity and consistency in output.Q: What are the main benefits of the precision spindle and hardened bed feature?

A: The precision spindle ensures accurate rotation and minimal runout, while the hardened bed resists wear, providing long-lasting accuracy in machining and reducing maintenance needs over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free